PREVIOUS

GAGE BLOCK HEADER PAGE

Micrometer Checking Sets

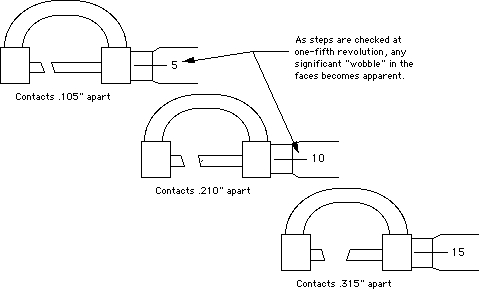

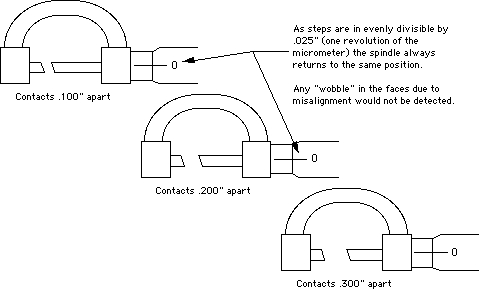

Micrometer Checking Sets are used to check 0-1 Inch or 0-25mm micrometers. The blocks are selected to check the lead screw of the micrometer at different rotational positions of the micrometer spindle. This enables checking for any significant deviations of the screw and orientation of the spindle contact face at the same time.

English System

Metric System

The sizes contained in these sets are: .105, .210, .315, .420, .500, .605, .710, .815, .920, and 1.000

The sizes contained in these sets are: 2.5, 5.1, 7.7, 10.3, 12.9, 15.0, 17.6, 20.2, 22.8, and 25.0mm

Steel

These sets are primarily meant as working sets to calibrated 0-1 Inch or 0-25mm micrometers. The accuracy of the gage blocks is better than 4 times the resolution of most micrometers. Steel is the material of choice as the thermal expansion of the gage blocks will be roughly equal to the thermal expansion of most micrometers.

Catalog No. |

Grade |

RS 10.A |

AS1 |

Catalog No. |

Grade |

RS 10.MA |

AS1 |

GAGE BLOCK HEADER PAGE

GB20