|

|

|

|

BACK to

USE and CARE

|

|

|

|

GAGE BLOCK HEADER PAGE

|

|

|

Wringing Gage Blocks

|

|

|

Wringability is an important property of gage blocks. In fact, gage block specifications

recommend replacing blocks that have lost their ability to wring. Not everyone uses gage

blocks in wrung combinations, but wringability is a test on the integrity of the surface condition

of the gage block. Gage blocks that don’t wring may give erratic and unreliable results.

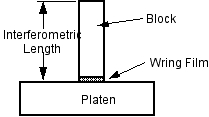

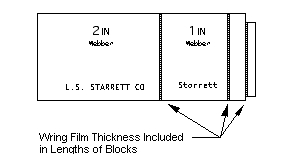

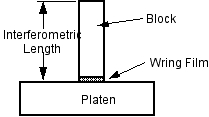

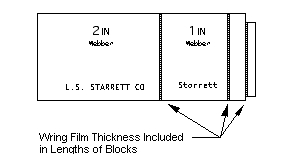

The fact that gage blocks wring is incorporated into the lengths of the blocks themselves. Gage

block length is defined as an interferometric measurement when the gage block is wrung to a

flat platen. This includes one wringing film in the defined length of the gage block.

|

|

|

|

|

|

|

|

This definition is very useful. When gage blocks are assembled in combinations, no additional

correction factor for wringing films needs to be added to the length of the combination.

|

|

|

|

|

|

|

|

Wringability itself may be defined as the ability of two surfaces to adhere tightly to each other in

the absence of external means. (They are not magnetized or clamped together.)

Wringing requires two smooth, flat surfaces with surface finishes of 1 microinch AA or better.

For gage blocks, it becomes difficult to wring surfaces if the flatness starts to exceed 5

microinches. The sources of the forces holding gage blocks together are thought to come

from:

1. Air pressure from the surrounding environment as the air is squeezed out when the

blocks are slid together.

2. Surface tension from oil that remains on the gage blocks or water vapor from the air acts

as a glue to hold them together.

3. When two very flat surfaces are brought into such close contact with each other, this

allows an interchange of electrons between the atoms of the separate blocks, which

creates an attractive molecular force. (This force will remain even in a vacuum or if no oil

or water is present on the blocks.)

The last two sources are thought to be the most significant.

Preparation of Gage Blocks Prior to Wringing

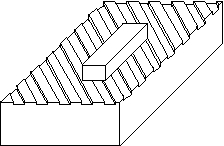

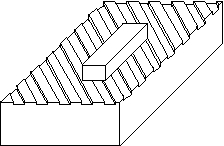

Make sure that the blocks to be wrung are free from nicks and burrs. It is important that all

nicks and burrs be removed BEFORE attempting to wring blocks together because a burr on

one block may damage the surface of the other block.

Blocks may be checked for burrs with a gage block stone before wringing. A gage block stone

with serrated grooves is recommended because it gives a better "feel" for nicks and burrs that

catch the edges of the serrations. Badly nicked surfaces will click as a nick passes along the

serrations.

|

|

|

|

|

|

|

|

Wringing Gage Blocks

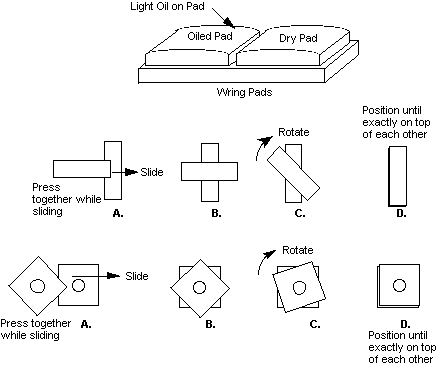

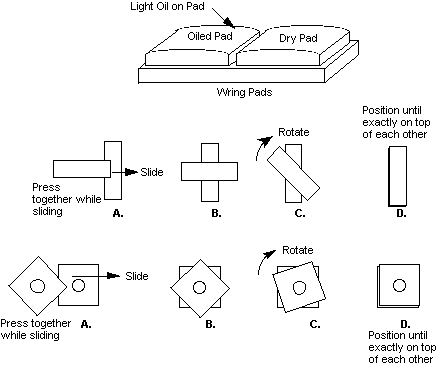

1. Make sure that blocks are clean.

2. Wipe the surfaces of the blocks to be wrung gently across the oiled Wring Pad.

(See figures below.)

3. Wipe these surfaces on the dry pad, removing as much oil as possible.

4. Slide the surfaces of the blocks together as shown. Apply pressure while sliding the blocks.

The blocks should slide together without any feel of bumps or scratching, and should adhere

to each other strongly after being rotated into place.

|

|

|

|

|

|

|

Wringability is an important property of gage blocks, and is fortunately a quality that can be

controlled and monitored readily by the user of the blocks. With proper use and care, gage

blocks will provide long, reliable, accurate service.

|

|

BACK to

USE and CARE

|

|

GAGE BLOCK HEADER PAGE

|

|

|

GB46

|

|

©2018, Webber Gage Division, The L. S. Starrett Co, Westlake, Ohio , 44145

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|