Stoning Gage Blocks.

Will stoning a gage block change its size? The answer to that question is No.....and Yes. It

depends largely on the condition of a block. A block in good condition will not be affected by

light stoning. The purpose of stoning is to remove portions of the block that have been raised

above the true gage surface by nicks or scratches which can contribute to more variation

during calibration or large readings. Stoning will remove this small amount of raised material.

Repeatability of readings is improved, and sizes appear to be truer to their original tolerances.

Blocks will wring together better.

1. Stoning is to be performed only on used gage blocks where the surface finish may be

degraded by scratches or small nicks.

2. Make sure the stone is clean and dry--free from any dirt or abrasive compound. Abrasives

on the stone may lap the block and significantly alter its size.

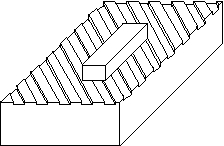

3. With a light amount of pressure, stroke the block across the serration two or three times.

(Forward, back, and forward.) It is not recommended that more than light pressure be used

unless necessary to remove nicks and burrs.

4. Listen and feel for nicks and burrs that might be present. If the block glides easily across the

stone without a scraping sound or clicking or jumping across the serration, then stop. Flip

the block over, and repeat on the other side.

5. If nicks and burrs are detected, repeat the procedure but not more than twice more. The

pressure may be increased each time as needed to try to remove the nicks and burrs. Use

not more then seven strokes per session.

6. If repeated attempts are unsuccessful at removing the burrs, examine the block for damage.

It is not likely a block would be wringable in this condition.

Rusted Gage Blocks.

The condition of rusty blocks may be greatly improved by stoning the blocks after the stone has

been wetted with kerosene. While this may temporarily improve the utility of the block, this will

not permanently remove the corrosion or halt its advance.

1. Take a cotton swab and dampen it with kerosene.

2. Wipe the stone with the dampened swab. A film of kerosene should be seen on the stone,

but the stone should not be dripping wet.

3. Stone as before, using whatever pressure is necessary. It may be necessary to be quite

aggressive to remove the corrosion.

4. If the corrosion cannot be removed after repeated tries, then the block is considered to be

damaged.

5. Keep the stone dampened as the kerosene evaporates.

Stoning Pressures.

1. Light Stoning: 1 to 1.5 lbs pressure

2. Medium Stoning 2.5 to 3.5 lbs pressure

3. Heavy Stoning More than 6 lbs pressure

|

|