|

|

|

|

BACK to

USE and CARE

|

|

GAGE BLOCK HEADER PAGE

|

|

|

Acclimation Time for Gage Blocks

|

|

|

The table below gives our recommended acclimation times for STEEL gage blocks, either on an

aluminum or steel soaking plate, or in open air. (With maximum possible surface area of contact.)

NOTE: We do not recommend soaking gage blocks to temperature on a granite surface plate.

Granite is a very poor conductor of heat. While the granite may feel cool to the touch, it may

localize the heat from the gage block on the surface of the granite and insulate the block from

its environment.

|

|

|

|

Steel Acclimation Table

|

|

|

|

On a soaking plate*

|

In Open Air

|

Given by the formula:

Time(minutes) = 4L +7

where L = Length of block (in inches)

But, Time not less than 8 minutes

nor greater than 60 minutes.

|

Given by the formula:

Time(minutes) = 30L +50

where L = Length of block (in inches)

But, Time not less than 60 minutes

nor greater than 300 minutes.

|

|

|

|

*NOTE: For larger gage blocks, the mass of

the blocks may change the temperature of

the soaking plate.

|

|

|

|

Other Materials:

Other gage block materials have different thermal values of thermal conductivity, and hence

will have different acclimation times than steel. For gage blocks made from materials other than

steel, multiply the recommend acclimation time in the above table by the values below.

|

|

|

|

Material

|

Relative Thermal Conductivity

|

croblox® (chrome-carbide)

|

1.2

|

tungsten-carbide

|

1.5

|

ceramic

|

2.2

|

|

|

|

|

The above tables come from experiments conducted by Webber Gage.

Gage Blocks were heated to 80°F, and allowed to cool to 68°F. A hole was drilled and tapped in the

side of each gage block tested, and a thermistor was attached. The thermistor based temperature

measurement system has a resolution of .01°F with a measurement uncertainty of .03°F.

For placement on the soaking plate, it was deemed that the blocks had reached equilibrium when either

there was no change in temperature of the test blocks for two consecutive time periods, or the

temperature of the test block was within .03°F of the soaking plate for two consecutive periods. (A test

period was about 90 seconds.)

In air, it was deemed the blocks had reached thermal equilibrium when either there was no change in

temperature of the test blocks for two consecutive periods, the change was less than .03°F for three

consecutive periods, or the recorded temperature of the test block became warmer from one period to

the next.

From the experiment, it was observed that:

1) Square style blocks only take about 10% longer to acclimate to temperature than do rectangular

style blocks.

2) There was practically no difference in time to cool a 20-inch block as compared to a 10-inch block.

3) Most of the temperature change occurred within the first 10% to 20% of the time allotted. Most of

the acclimation time was removing the last one-half degree of temperature.

|

|

|

|

|

|

|

|

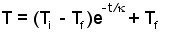

It is assumed that the temperature of a gage block acclimating to temperature will be given

by the following formula:

|

|

|

|

|

|

|

where T = temperature of the block after an elapsed time

t = elapsed time

Ti = initial temperature of the block

Tf = final temperature of the block (temperature of environment)

k = the time constant Its value is dependent on:

|

|

|

|

a) the material of the gage block (its thermal conductivity)

b) the thermal conductivity of the soaking plate or air (thermal sink)

c) the amount of surface area in contact with the thermal sink

|

|

|

|

Note: The times given in the Steel acclimation Table represent about 6 time constants as used in the formula for

acclimation to temperature. It is also assumed that the maximum possible surface area was placed in contact with

the thermal sink.

|

|

|

|

BACK to

USE and CARE

|

|

GAGE BLOCK HEADER PAGE

|

|

|

GB51

|

|

©2018, Webber Gage Division, The L. S. Starrett Co, Westlake, Ohio , 44145

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|