|

|

|

|

BACK TO

SELECTING

GRADE

|

|

|

|

ANGLE GAGE BLOCK HEADER PAGE

|

|

|

|

|

|

Sources of Error Using an Angle Block

|

|

|

|

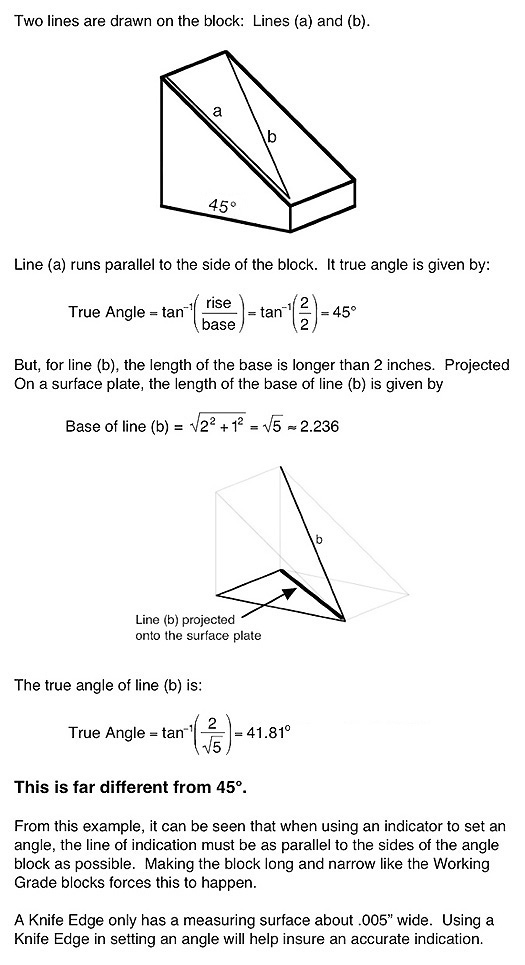

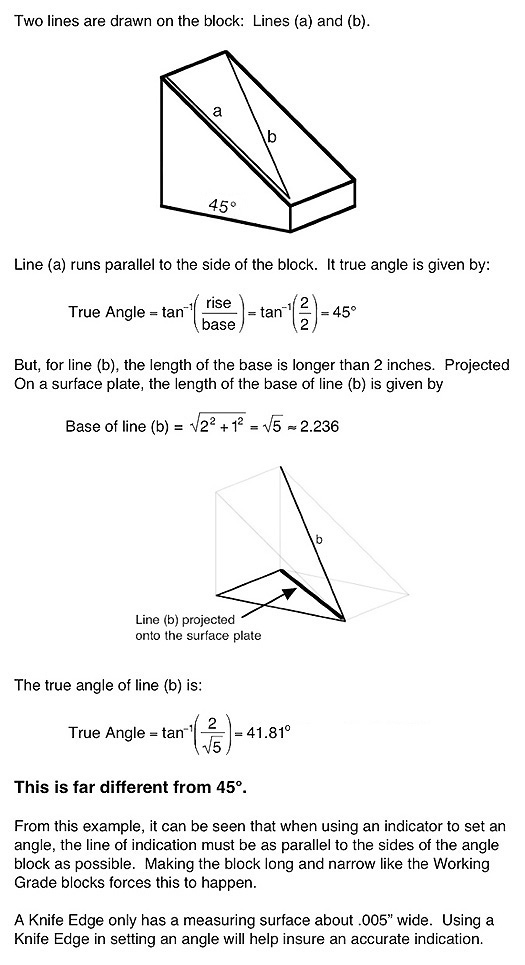

WHEN USING AN INDICATOR:

Consider a 45° angle block with a surface of 1" x 2".

|

|

|

|

|

|

|

|

WRINGING:

|

|

|

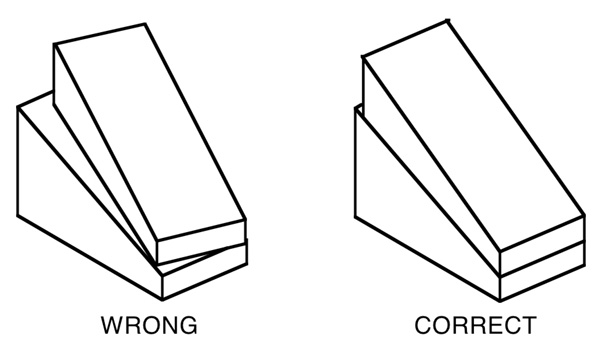

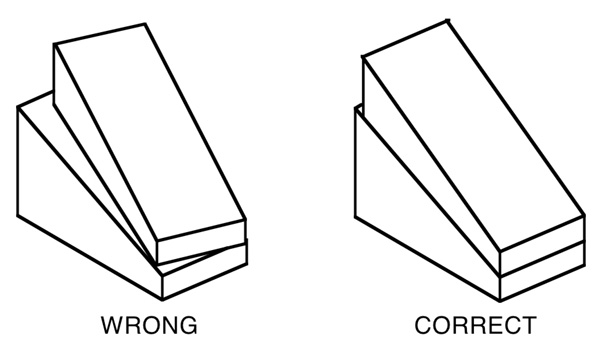

Angle gage blocks must be wrung with their sides parallel to each other.

Else, as seen above, it is impossible to set a true angle.

|

|

|

|

|

|

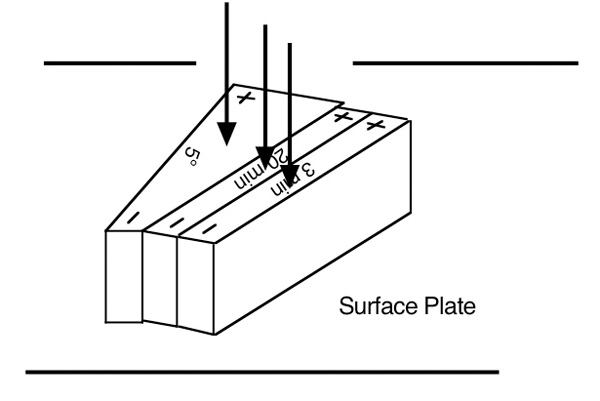

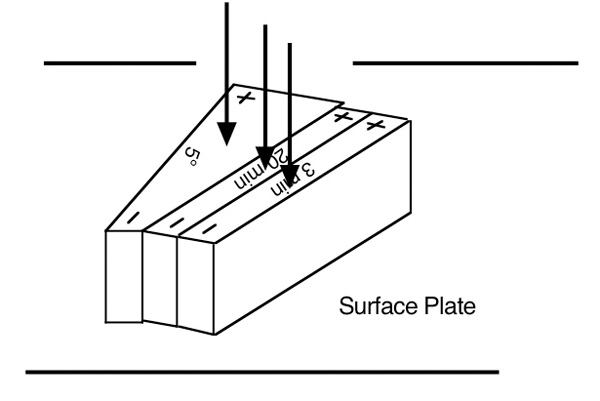

It is recommended that the sides of the angle blocks be made parallel by

aligning them against a flat surface after wringing them together.

|

|

|

|

|

|

|

BACK TO

SELECTING

GRADE

|

|

|

|

|

|

|

|

ANGLE GAGE BLOCK HEADER PAGE

|

|

|

AG11

|

|

©2018, Webber Gage Division, The L. S. Starrett Co, Westlake, Ohio , 44145

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|