GAGE BLOCK HEADER PAGE

PREVIOUS

ACCESSORY HEADER PAGE

HALF-ROUND ACCESSORY JAWS

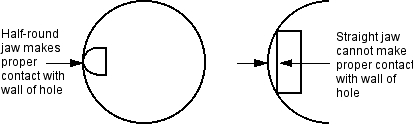

Half-round jaws are primarily used to make "go-no-go" or snap gages to verify the diameter of a hole. The radius on the jaws is to allow the jaw to come into contact with the wall of the hole. This cannot be done with a straight jaw.

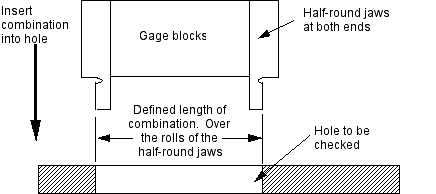

Gage blocks and half-round jaws are assembled into a combination. The combination is inserted into a hole. Measurement is made by checking whether the combination fits into the hole, or it doesn’t.

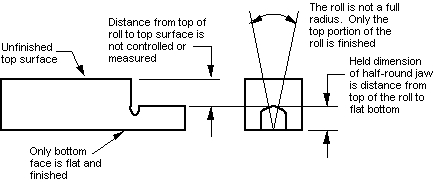

The specified tolerance for half-round jaws is ±32µin. (±0.80µm). However, because the distance over the roll of these jaws is so difficult to measure, Webber reduces our manufacturing tolerance to ±20µin. or ±0.50µm to allow for any measuring errors. For B89.1.9 specifications, click here. When these jaws are included as pairs in sets, they are matched together so that the sum of the errors is not larger than ±20µin. or ±0.50µm. Thus, if one jaw measures +15µin., the jaw paired with it is not larger than +5µin. It would be preferable to use a jaw with a negative measurement, if one was available. Pairing jaws is done to reduce the accumulation of errors to the user. (By specification, jaws sold as pairs must have a combined size tolerance not larger than ±40µin. or 1.0µm.) For users ordering a single replacement jaw, the replacement will be within the normal tolerance of ±20µin. or ±0.50µm.

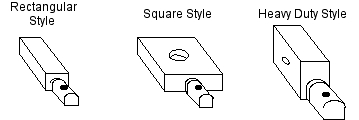

Construction of Half-Round Jaws:

Available As:

Rectangular Style |

Square Style |

Heavy-Duty Style |

RA 1. .250 in. Thick (steel) RA 2. .200 in. Thick (steel) RA 3. .100 in. Thick (steel) RA 101. 5.0mm Thick (steel) . |

SA 1. .125 in. Thick (steel) SA 2. .250 in. Thick (steel) SA 101. 3.0mm Thick (steel) SA 102. 6.0mm Thick (steel) |

HDA 1. .500 in. Thick (steel) . |

GAGE BLOCK HEADER PAGE

PREVIOUS

ACCESSORY HEADER PAGE

GB73